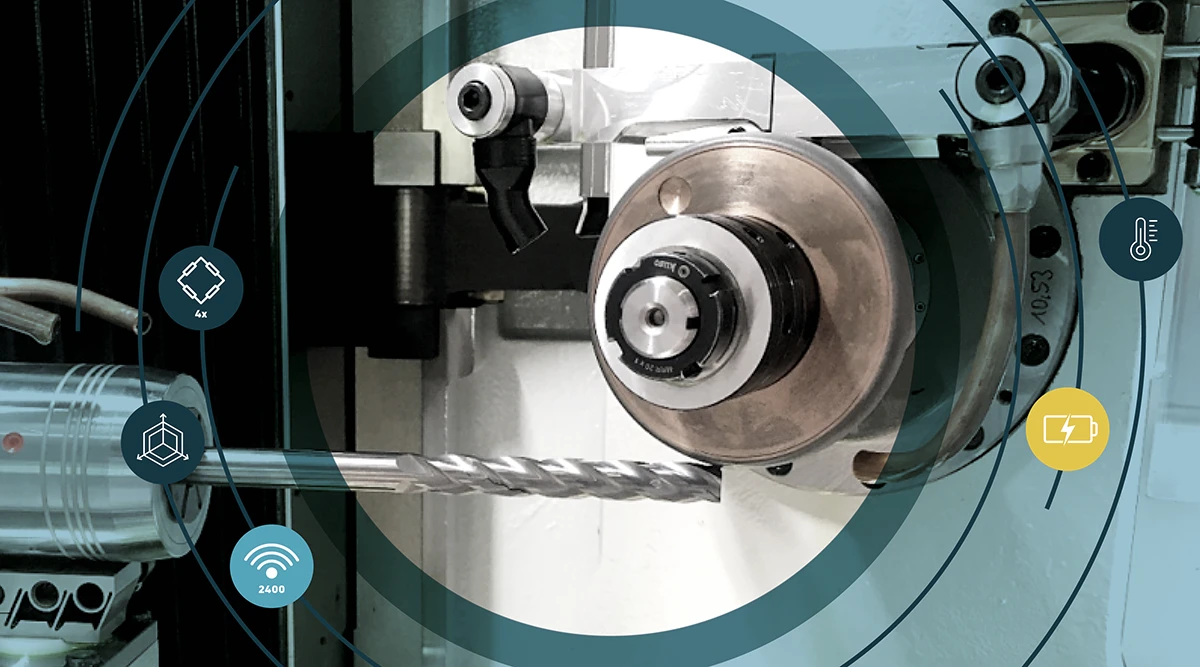

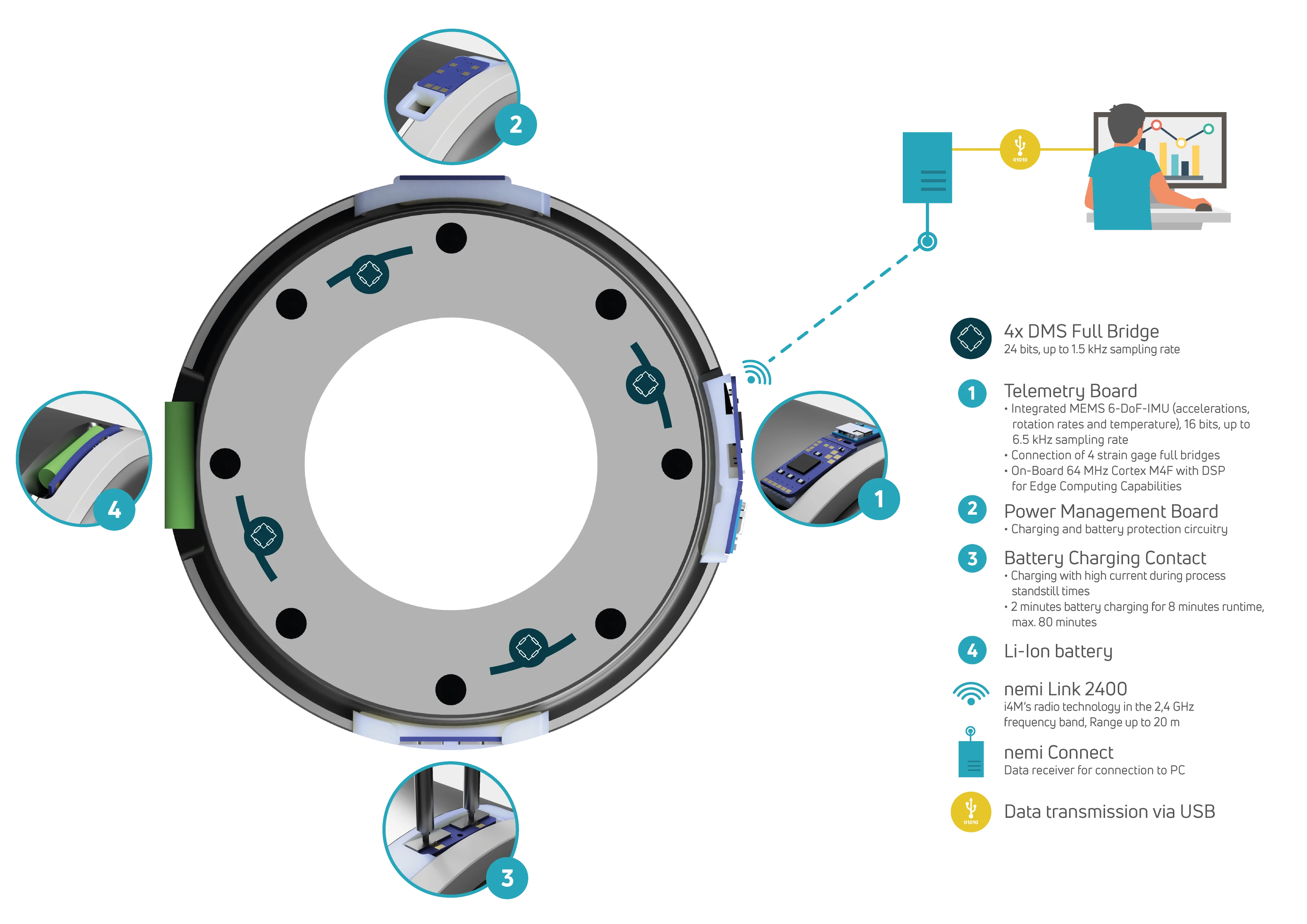

Wireless integration of radio sensors in a grinding spindle of a machine tool to measure vibrations and forces occurring during the grinding process.

Institute of Production Engineering and Machine Tools, Leibniz University Hannover

2021 / 2022

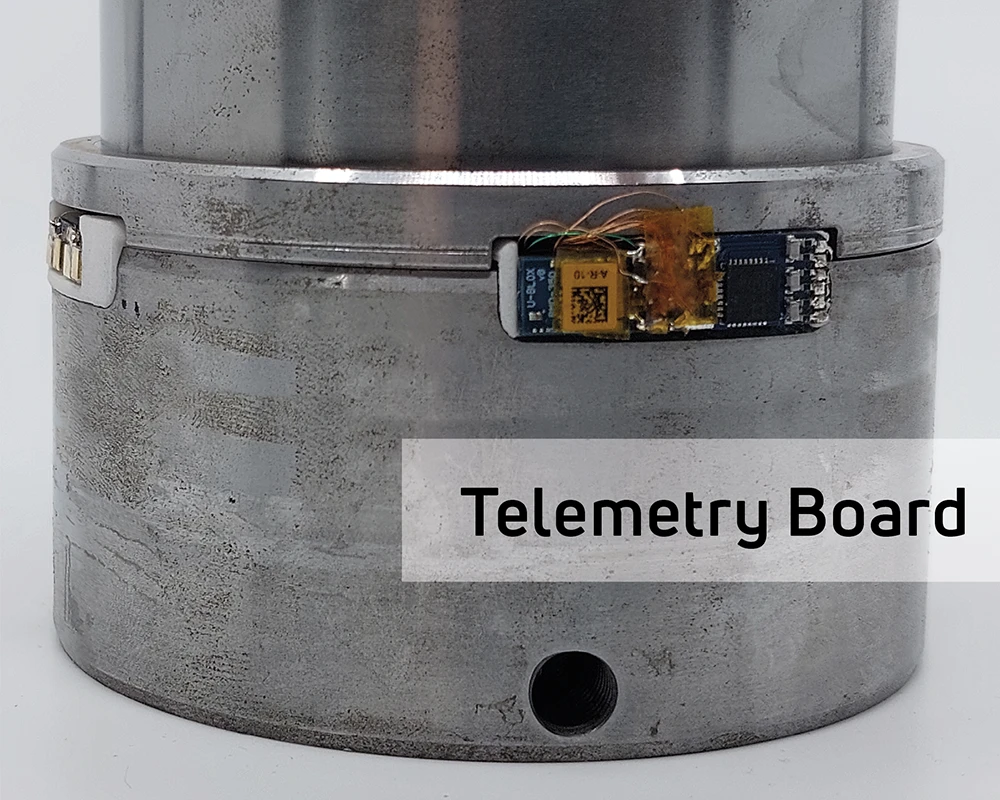

„Within a very short time, i4M technologies designed, developed and manufactured a fully functional, wireless telemetry system for the condition monitoring of a tool grinding machine. The telemetry system is very small, battery-powered and fully integrated into the grinding spindle. The system reliably

transmits from a machine tool. This solution enables structural integration of sensor technology on rotating machine components, so that process forces can be detected close to the point of action and additional cost-intensive measurement technology components can be dispensed with. I also articularly

liked the uncomplicated and goal-oriented cooperation with the team.“

M.Sc. Henning Buhl

Head of Department Machine Components

Institute of Production Engineering and Machine Tools,

Leibniz University Hannover

Martin Noll

i4M technologies GmbH

Foersterstr. 5

52072 Aachen

Germany

+49 241 56 00 22 00

sales@i4m-tech.de