Objective

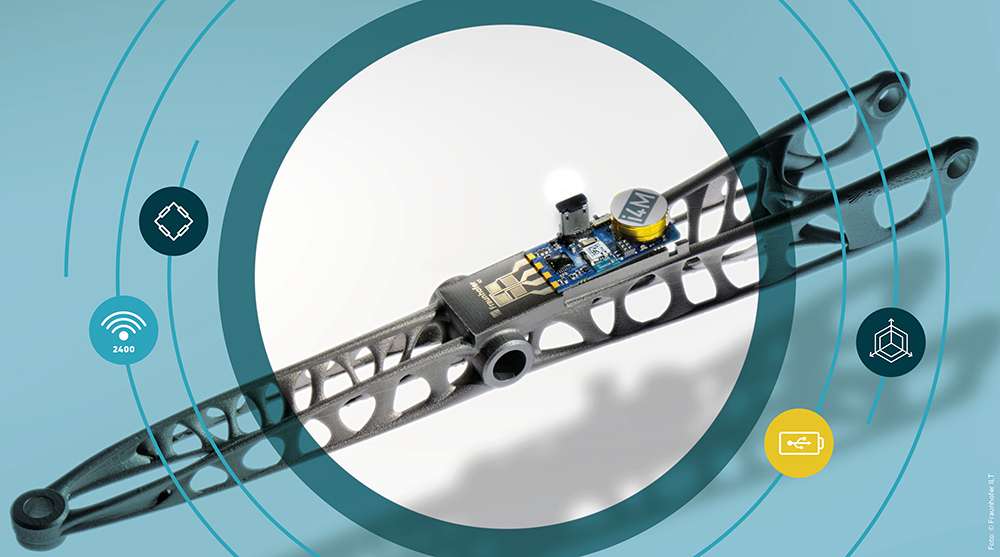

- Demonstrator of a smart component using i4M's highly efficient telemetry and a direct connection of a 3D printed strain gauge

- Collection of component condition data such as mechanical and thermal loads using highly integrated smart measurement technology to realize intelligent machine elements

Partner

Fraunhofer ILT – Institute for Laser Technology

Period

since 2019

Challenges

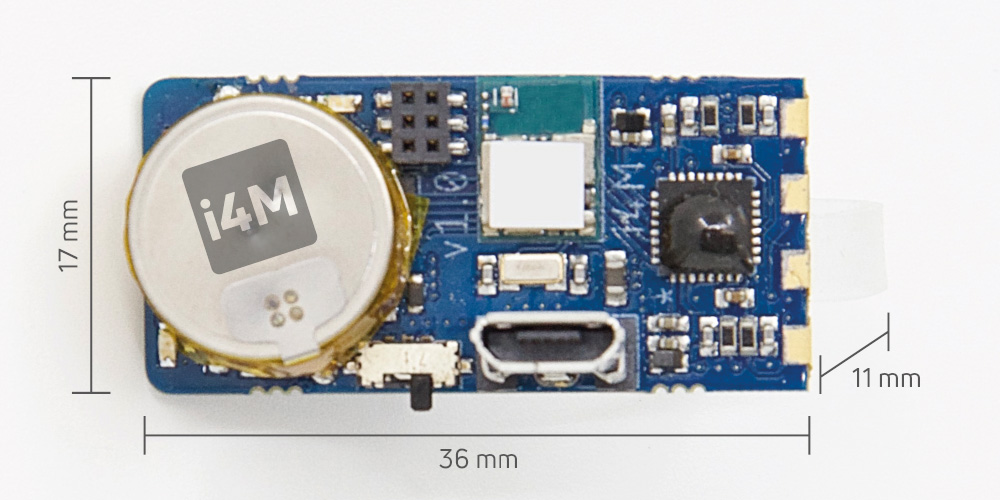

- Small installation space

- Long battery life

- Direct connection of the 3D printed strain gauges

Realization

- Measuring system consisting of a transmitter module integrated in the component including battery and a receiver module for data acquisition

- Connection of a strain gauge full bridge or a resistance thermometer to SMD pads directly on the transmitter module

- MEMS sensor technology integrated on the transmitter module for measuring accelerations and rotation rates

- Wireless data transmission with nemi Link 2400, i4M's radio technology in the 2.4 GHz frequency band, via integrated antenna to a receiver module nemi Connect

- Charging of the built-in battery via Micro USB cable

- Software for live data display for demonstration purposes at trade shows

Advantages

- Wide use of highly integrated measurement technology to measure component loads even in the smallest applications

- Highly efficient wireless measurement technology and long battery life due to robust radio technology nemi Link 2400

- Capability for edge computing on the transmitter module

Publications

DMS-Sensoren aus dem 3-Druck mit Low-Power-Funk-Telemetrie

Rehberger, Matthias; Noll, Martin-Christopher | Elektronik Praxis, 17. Ausgabe 2020, 14.09.2020, S. 46-48

3D printing improves strain gauge sensor manufacturing

Vedder, Christian; Noll, Martin-Christopher; Rehberger, Matthias | LaserFocusWorld, 21.04.2021