Our highly integrated and wireless individual solutions turn your components and machines into smart products: They obtain data directly from the component and thus enable digital business models such as predictive maintenance - without requiring complex adjustments to the component design.

We find the right sensor technology for you and couple it with our ultra-high efficiency technology.

Whether you want to monitor forces, loads, vibrations, temperatures or other measured variables, we will find the right sensors for you. Together with our highly efficient radio technology, we develop smart sensors that are adapted to your application and enable you a completely wireless machine monitoring.

Strain

Force / Torque

Pressure

Flow

Mass

Acceleration / Vibration

Structure-Borne Sound

Airborne Sound

Temperature

Humidity

Rotation Rate

Rotation Angle

Inclination

Distance

Position

Fill Level

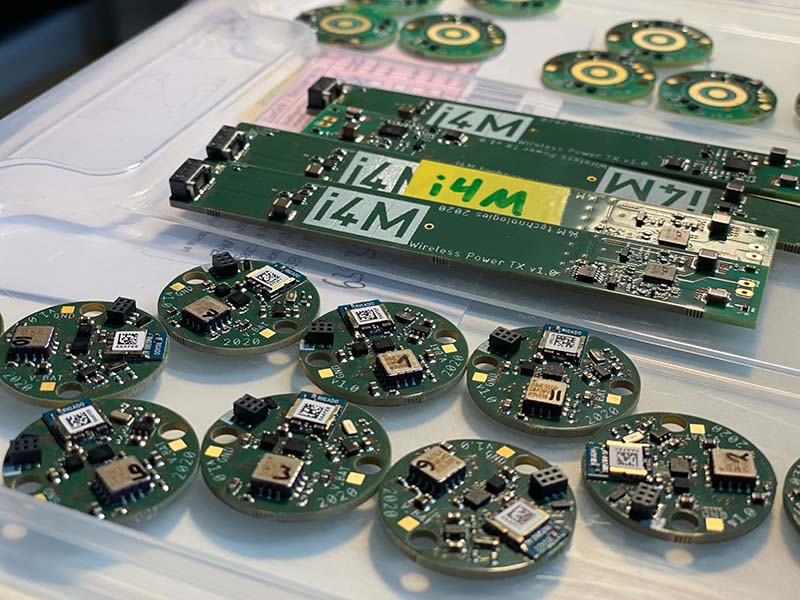

nemi DAQ nano is a tiny wireless multi sensor with energy harvesting module for measuring and monitoring strains, forces, displacements and much more. It is designed to meet the needs of many demanding use cases without the cost of custom development.

nemi G+ nano is a tiny, wireless sensor with Energy Harvesting module for measuring and monitoring accelerations, vibrations and rotation rates. Because of the compact and lightweight design nemi G+ nano can easily be integrated in smallest installation spaces and turns your components and machines into smart products.

Use Case

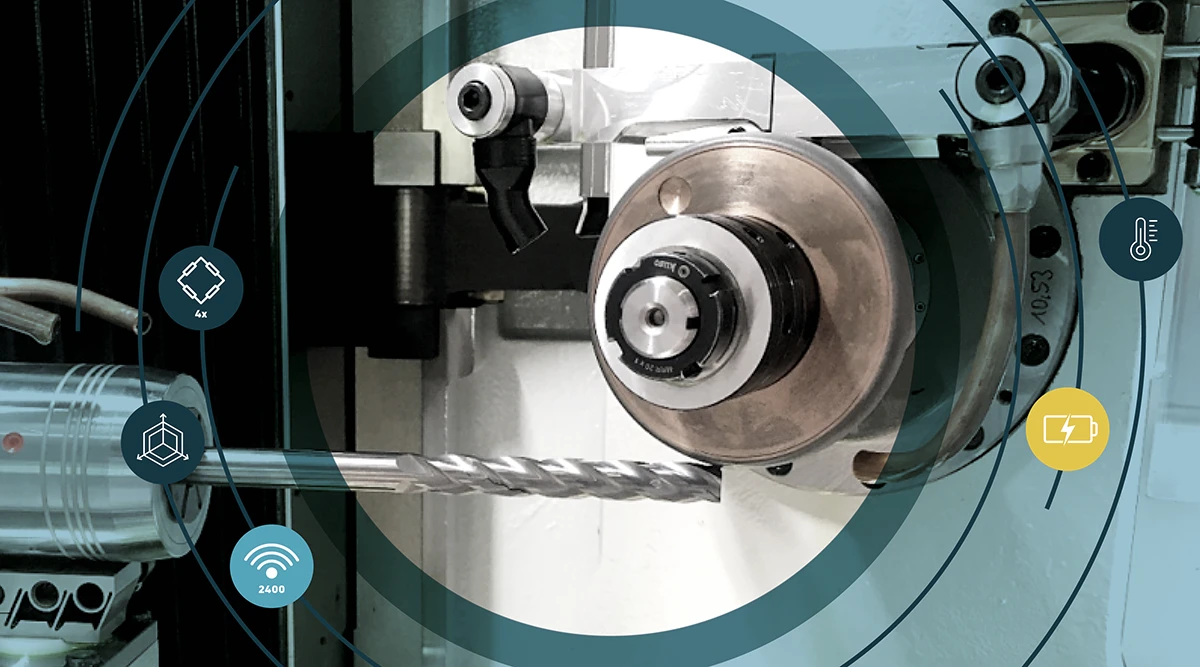

Wireless integration of radio sensors in a grinding spindle of a machine tool to measure vibrations and forces occurring during the grinding process: The sensory spindle thus enables an autonomous, self-monitoring and self-regulating grinding process.

Challenges

Smallest installation space

Battery charging without retooling

Wireless data transmission from the inside of the machine

Electromagnetic interference

Solution & Advantages

Structure-integrated Condition Monitoring

Monitoring sensitive properties by integrated sensors

Reliable data despite seal and housing

Autonomous, fast battery charging

In the space of a 1-euro coin, we accommodate completely wireless sensor modules. In addition to signals from for example strain gauges, temperature and pressure sensors, the modules also record acceleration and rotation rates in and around all three spatial directions or axes. All data can be provided live via radio data transmission.

To make your machine element even smarter, data pre-evaluation / data reduction can be performed via edge computing on the sensor module.

High-performance radio technology: High live sum sampling rate per radio channel of up to 36 kHz at 24 bits/sample. Up to eight radio modules per radio channel can be coupled to one receiver. Our fully synchronized radio networks operate with time deviations below 20 microseconds and low latencies.

Years of battery life: Minimal power consumption in operation and sleep mode due to i4M's ultra-high efficiency technology

Integrated computing power for online algorithms and edge computing

Highly integrated and compact design: adjustments to the component design can be avoided

Completely wireless: Powered by battery, rechargeable battery or energy harvesting and with integrated radio data transmission

Energy Harvesting possible depending on location (e.g. by means of Peltier elements or solar cells)

Robust and extensively tested: Under oil, in large gearboxes, under strong electromagnetic interference fields, on various machine elements, streetcars and wind turbines.

Various sensors can be connected:

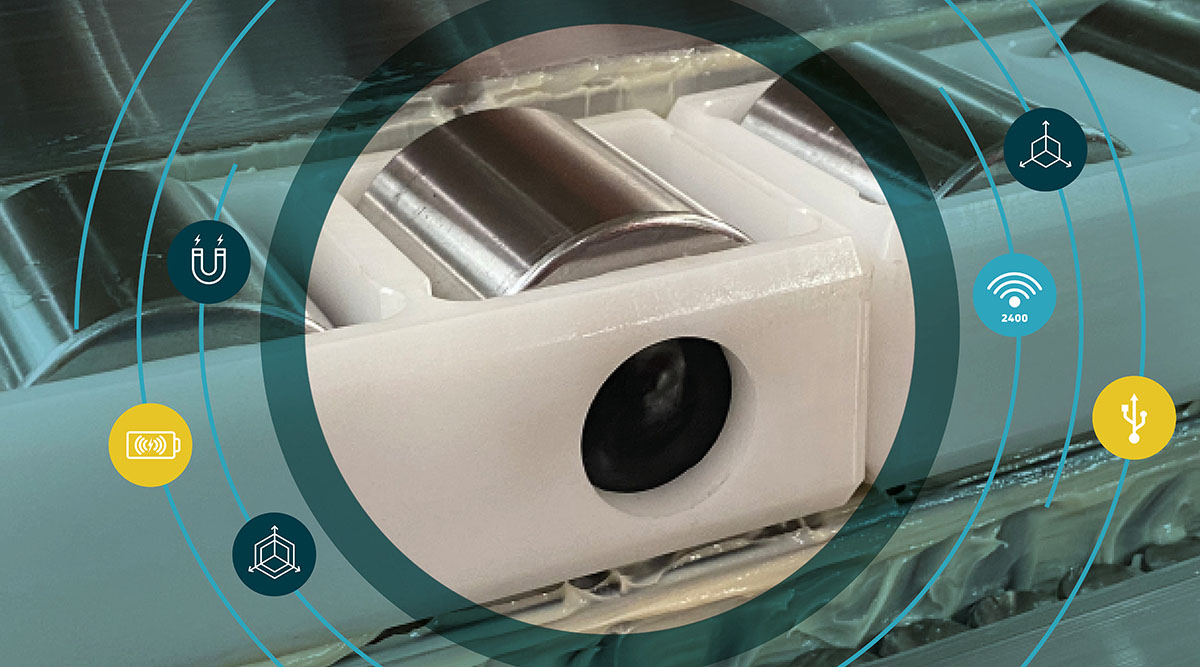

Use Case

To record the rotational movement of rolling elements in large bearings, we have developed a measuring system consisting of sensors integrated in the rolling element, whose collected data are transmitted wirelessly to a receiver. In this way, a rolling element became a smart machine element.

Challenges

Small installation space

Contactless battery charging

Optimal radio performance despite metal & lubricant

Solution & Advantages

Fully integrated molded measuring system

Highly efficient wireless measurement technology

Reliable data transmission

Edge computing in the rolling element

We develop customized solutions for your application on the basis of extensive experience from various industries and our completely self-developed hardware and firmware. In the shortest possible time, we thus arrive at the first prototypes with which data can already be obtained.

Upon request, we can take over the data analysis. To reach your goal we use the most modern algorithms according to the current state of science and technology. We subsequently apply these algorithms directly in the sensor modules, thus enabling the reduction of Big Data to Smart Data by edge analytics. This saves energy during data transmission, increases battery runtimes and reduces complexity in the subsequent data handling steps (storage, analysis, presentation).

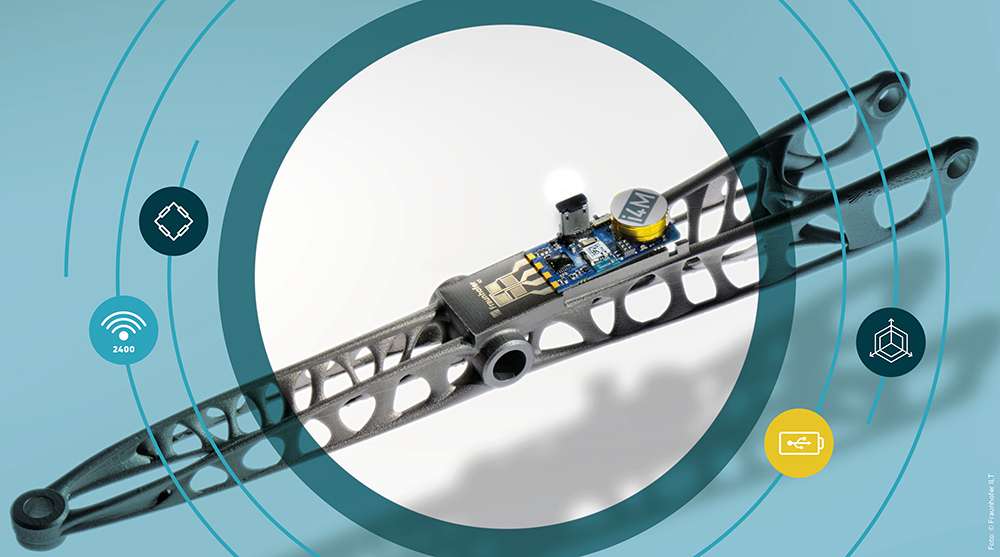

Use Case

In a project with Fraunhofer ILT, we have developed highly integrated, wireless measurement technology with a direct connection of a 3D printed strain gauge that can be used for the smart recording of mechanical and thermal loads on components. This technology can be used in a wide range of applications and makes machine elements smart.

Challenges

Compact installation space

Long battery life

Direct connection of the 3D printed strain gauges

Solution & Advantages

Wide range of use even in the smallest applications

Highly efficient wireless measurement technology

Edge computing capability

Martin Noll

i4M technologies GmbH

Foersterstr. 5

52072 Aachen

Germany

+49 241 56 00 22 00

sales@i4m-tech.de